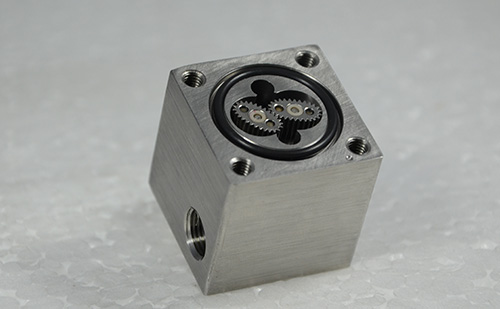

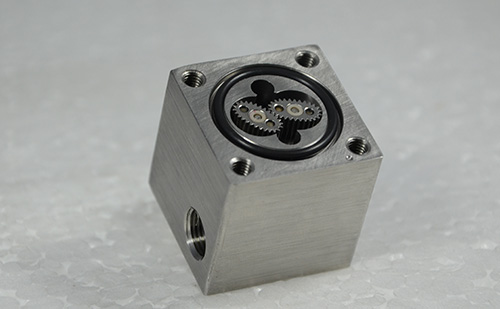

lubricating grease mini flowmeter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD has a completeplanning, design, research and development, manufacturing, sales, servicesystem, is committed to providing high-quality,high-performance micro flowmeters,ovalgear flow meter ,electromagnetic flow meter,mass flow meter,piston flowmeter,gear flow meter,gear pump,gear metering pump for professional channelcustomers and end customers at home and abroad. Since the 1980s, it has reliedon a strong technical R&D team to focus on the field of flow meter measurement,and developed ultra-miniature, high-precision, high-frequency, high-pressure,and large-scale flow metering equipment. Today, there are more than 500,000units (sets) products are serving all corners of the country and are widelyused in polyurethane, dispensing, hydraulic, odor, petrochemical, power,military, aerospace, scientific research, nuclear industry, cement, metallurgy,steel and other industries.

lubricating grease mini flowmeter

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

Base deep gear wheel flowmeter on the production of all caliberflowmeters, basically have stock inventory, which in itself shows that thecompany"s funds and sales are good, we dare to do inventory. Hee Oval gear flowmeter has two national inventions, In the process of production qualitycontrol, starting from the beginning of the procurement of raw materials, everyproduction and precision machining links careful examination, each of the Ovalgear flow meter factory must be continuous calibration test. Processinstallation ISO9001 quality management system strictly enforced, the producthas the CE, SGS and other EU certification. Our company has "the qualityof Germany, China"s manufacturing" as the slogan to create a world-classoval gear flow, real automation instrumentation industry Benchmarking business.

lubricating grease mini flowmeter

The Ovalgear flow meter is a volumetric flow meter. The metering chamber is composed ofupper and lower end caps. The shell is formed by an oval gear rotor. The gearrotor meshes with the rotating shaft to convey the fluid. The permanent magnetarranged in the rotor is used for the detection of the rotor rotation. Twosensor holes are placed on the upper end to cover the detection sensor. Asealing ring is installed between the housing and the upper and lower end capsto prevent leakage of the measurement fluid. The base depth flowmeter is madeof a material with high wear resistance so that the flowmeter Can guaranteehigh precision measurement within the long service life.

lubricating grease mini flowmeter

Technicaldata of Gear type flow meter

Model | K-factor | Minimum flow | Flow range | Accuracy |

G0.025 | 0.025ml | 0.001L/Min | 0.008~2L/Min | 0.5% |

G0.04 | 0.04ml | 0.004L/Min | 0.2~4 L/min | 0.5% |

G0.1 | 0.4ml | 0.008L/Min | 0.01~8L/min | 0.5% |

G0.2 | 0.245ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G0.4 | 0.4ml | 0.01L/Min | 0.16~16 L/min | 0.5% |

G1 | 1.036ml | 0.02L/Min | 0.4~80 L/min | 0.5% |

Commonfault causes, troubleshooting

a. Thegear does not rotate: The gear is jammed by debris, the gear and cavity need tobe cleaned, and the filter is cleaned or replaced.

b. Thesmall flow error is too large: The flowmeter is installed in the wrongdirection, the best position goes up and down, or there are impurities to blockthe gear and need to be cleaned.

c. Theflow error is too large: The actual use flow range is less than or far greaterthan the flowmeter range. The corresponding flowmeter must be selected.

d. Noflow sensor signal: The gear is stuck or the circuit is connected incorrectlyor the circuit is damaged. The gear and cavity must be cleaned, or the circuitmust be correctly connected or replaced.